Science

Innovative Process Enhances Manganese Ion Recovery from Wastewater

A recent study has unveiled an innovative approach for recovering manganese ions from hydrometallurgical tailings water, which could significantly reduce resource wastage and environmental impact. The research highlights the efficiency of the nucleation crystallization pelleting process, offering a viable solution to one of the industry’s pressing challenges.

The study, led by a research team at [Institution Name], provides practical insights into how this method can be applied at scale. By focusing on the recovery of high-concentration manganese ions, the process not only addresses the recycling of valuable materials but also minimizes the ecological footprint associated with mining operations.

Efficiency and Applicability of the Process

The nucleation crystallization pelleting process is characterized by its ability to efficiently extract manganese ions from contaminated water sources. According to the research findings, this method demonstrates a recovery rate exceeding 90%, showcasing its potential in various industrial applications. Researchers utilized advanced techniques to optimize the crystallization process, leading to the formation of high-purity manganese pellets.

This innovation is timely, as the demand for manganese in battery production and steel manufacturing continues to rise. The ability to reclaim manganese from tailings not only enhances resource efficiency but also contributes to more sustainable practices within the industry.

The study emphasizes that traditional methods of manganese extraction often result in significant waste and environmental degradation. By implementing the nucleation crystallization pelleting process, industries can transition towards more sustainable operations, reducing both waste and adverse environmental effects.

Broader Implications for the Industry

The findings from this research hold broader implications for the mining and metallurgical sectors. As industries face increasing pressure to adopt sustainable practices, the adoption of such innovative processes will be crucial. This method not only conserves resources but also aligns with global efforts to minimize the environmental impact of industrial activities.

The research team underscores the importance of further exploration and development of this process. By refining the technology and increasing its applicability, the potential for widespread adoption grows. This could pave the way for a new standard in manganese recovery, ultimately transforming how industries approach resource management and environmental stewardship.

In conclusion, the nucleation crystallization pelleting process represents a significant advancement in the recovery of manganese ions from hydrometallurgical tailings water. Its high efficiency and low environmental impact position it as a leading solution in the quest for sustainable industrial practices.

-

Science2 months ago

Science2 months agoOhio State Study Uncovers Brain Connectivity and Function Links

-

Politics2 months ago

Politics2 months agoHamas Chief Stresses Disarmament Tied to Occupation’s End

-

Science1 month ago

Science1 month agoUniversity of Hawaiʻi Joins $25.6M AI Project for Disaster Monitoring

-

Science4 weeks ago

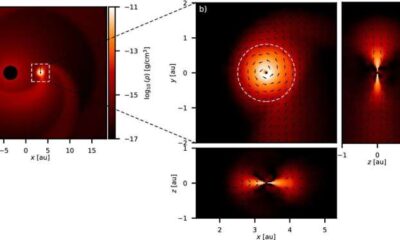

Science4 weeks agoALMA Discovers Companion Orbiting Giant Star π 1 Gruis

-

Entertainment2 months ago

Entertainment2 months agoMegan Thee Stallion Exposes Alleged Online Attack by Bots

-

Science2 months ago

Science2 months agoResearchers Challenge 200-Year-Old Physics Principle with Atomic Engines

-

Entertainment2 months ago

Entertainment2 months agoPaloma Elsesser Shines at LA Event with Iconic Slicked-Back Bun

-

World1 month ago

World1 month agoFDA Unveils Plan to Cut Drug Prices and Boost Biosimilars

-

Business2 months ago

Business2 months agoMotley Fool Wealth Management Reduces Medtronic Holdings by 14.7%

-

Science2 months ago

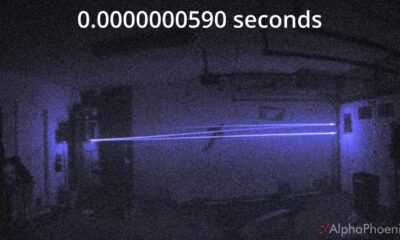

Science2 months agoInnovator Captures Light at 2 Billion Frames Per Second

-

Top Stories2 months ago

Top Stories2 months agoFederal Agents Detain Driver in Addison; Protests Erupt Immediately

-

Entertainment1 month ago

Entertainment1 month agoBeloved Artist and Community Leader Gloria Rosencrants Passes Away