World

Lockheed Martin’s F-35 Production Keeps Costs Competitive

The production of the Lockheed Martin F-35 Lightning II has reached impressive levels, securing its position as the most advanced fighter jet currently in operation. With a targeted output of over 156 F-35s annually, this high volume of production has effectively kept the per-unit costs lower than many other fourth-generation fighter jets in development. As of 2024, Lockheed Martin delivered 110 F-35s, with plans to increase that number to between 170 and 190 units in 2025.

Despite the F-35’s notorious reputation for delays and budget overruns—issues often highlighted in media reports—its production numbers reveal a different narrative. The program has consistently outpaced other fighter jet manufacturers. For context, while France’s Dassault struggles to deliver around two dozen Rafale jets annually, Lockheed Martin’s F-35 production has far surpassed all other non-Chinese frontline fighter jets combined.

Production Trends and Future Outlook

Lockheed Martin’s F-35 program achieved a significant milestone in 2025, surpassing the delivery of 1,200 jets across all three variants: F-35A, F-35B, and F-35C. This impressive production capability stems from the advantages of mass production, leading to a low flyaway cost. The average flyaway cost for the F-35A is approximately $82.4 million, a figure that positions it competitively against other high-end stealth fighters.

To compare, Boeing produced 14 F-15s and 11 F/A-18 Super Hornets in 2024, while the production of the F-16 remained steady with 16 units. However, the F-35’s scalability and efficiency in production give it a unique edge in the international market.

While Lockheed Martin stands out with its F-35 delivery, other fighter jets in production face challenges. For instance, the Super Hornet production line is set to close by 2027, and future orders are uncertain. Similarly, the Eurofighter program has encountered delays due to lack of new orders.

Cost Structure and Sustainment Challenges

Despite the low flyaway costs, the total expense of operating the F-35 becomes significantly higher when sustainment and additional costs are factored in. The Czech Republic, for example, reportedly paid $208.3 million for its F-35s, while Romania’s cost per aircraft was around $225 million. These prices reflect the additional expenses associated with spare parts, advanced systems, training, and infrastructure necessary for effective operation.

Notably, the UK contributes around 15% of each F-35 produced, benefiting from lower costs through domestic production. Other countries, including Israel and Germany, have also ordered the F-35 through the US’s Foreign Military Sales program, further expanding its global footprint.

The F-35’s export levels are unprecedented, as it remains the only fifth-generation fighter jet available to foreign customers. Countries such as Morocco and Turkey have expressed interest in acquiring the aircraft, though geopolitical considerations restrict sales to certain nations.

In summary, the combination of high production rates, competitive pricing, and a robust export strategy has solidified the F-35 Lightning II’s dominance in the global fighter jet market. As the program continues to evolve, it faces both opportunities for growth and challenges related to sustainment costs that could influence its long-term viability in the defense landscape.

-

Science2 months ago

Science2 months agoOhio State Study Uncovers Brain Connectivity and Function Links

-

Politics2 months ago

Politics2 months agoHamas Chief Stresses Disarmament Tied to Occupation’s End

-

Science1 month ago

Science1 month agoUniversity of Hawaiʻi Joins $25.6M AI Project for Disaster Monitoring

-

Science1 month ago

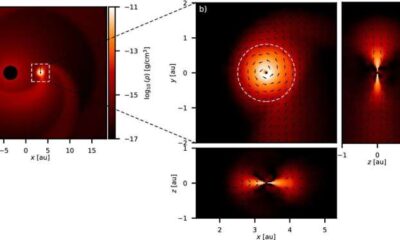

Science1 month agoALMA Discovers Companion Orbiting Giant Star π 1 Gruis

-

Entertainment2 months ago

Entertainment2 months agoMegan Thee Stallion Exposes Alleged Online Attack by Bots

-

Science2 months ago

Science2 months agoResearchers Challenge 200-Year-Old Physics Principle with Atomic Engines

-

Entertainment2 months ago

Entertainment2 months agoPaloma Elsesser Shines at LA Event with Iconic Slicked-Back Bun

-

World2 months ago

World2 months agoFDA Unveils Plan to Cut Drug Prices and Boost Biosimilars

-

Science2 months ago

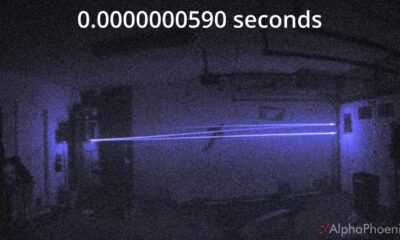

Science2 months agoInnovator Captures Light at 2 Billion Frames Per Second

-

Top Stories2 months ago

Top Stories2 months agoFederal Agents Detain Driver in Addison; Protests Erupt Immediately

-

Business2 months ago

Business2 months agoMotley Fool Wealth Management Reduces Medtronic Holdings by 14.7%

-

Entertainment2 months ago

Entertainment2 months agoBeloved Artist and Community Leader Gloria Rosencrants Passes Away