World

South Korean Shipyards Eye US Navy Fix Amid Shipbuilding Crisis

The U.S. Navy is grappling with significant shipbuilding challenges, prompting leaders from two South Korean shipyards to offer solutions. Under the leadership of President Donald Trump, who seeks to revitalize American shipbuilding, executives from HD Hyundai Heavy Industries and Hanwha Ocean assert their potential to enhance efficiency and effectiveness in naval construction.

During a recent House hearing, John Phelan, the U.S. Secretary of the Navy, openly acknowledged the gravity of the situation. “All of our programs are a mess,” he stated, revealing that even the Navy’s best program is currently six months behind schedule and 57% over budget. This long-standing issue of delays and cost overruns has plagued U.S. shipbuilding efforts, especially as the Navy seeks to counter an expanding Chinese fleet.

The South Korean shipyards have successfully produced some of the world’s most advanced warships for their own navy, consistently delivering on time and within budget. Recently, a CNN visit to the Hyundai and Hanwha facilities highlighted their efficiency. At Hanwha’s shipyard, officials showcased new infrastructure built specifically to accommodate an order for four advanced frigates. The construction of the facility took only 14 months, a testament to their operational speed.

Each of the frigates, measuring 122 meters and weighing 3,100 tons, will feature vertical launch systems for air defense missiles, along with capabilities to launch anti-ship missiles and torpedoes. The estimated time for completion is about three years, aligning closely with the ongoing delays in the U.S. Navy’s Constellation-class frigate program. These delays stem from the Navy’s numerous design changes to an existing model utilized by Italian and French navies.

South Korean shipbuilders attribute their success to a combination of skilled labor and streamlined logistics. Lee Jin, Vice President at HD Hyundai Heavy Industries in Ulsan, noted that the average worker in their facility has 16 years of experience. This continuity in workforce expertise is seen as a significant advantage. U.S. shipping expert Sal Mercogliano from Campbell University emphasized that the dual focus on military and commercial projects allows Korean shipyards to maintain a stable workforce, adapting to market demands more fluidly.

Historically, the U.S. made strategic decisions post-World War II that have impacted its current shipbuilding industry. Outsourcing commercial shipbuilding to countries like South Korea and Japan while focusing on military vessels is now viewed as a misstep. During a summit in August 2023, President Trump reiterated the goal of “Making American Shipbuilding Great Again,” which was first introduced during tariff negotiations with South Korea.

The South Korean shipyards are not resting on their laurels. Continuous improvements in manufacturing processes have been prioritized. A representative from Hanwha highlighted how the proximity of commercial and military shipyards enhances their adaptability. In contrast, U.S. military shipyards often operate under inconsistent Pentagon orders, which stifles investment in new technologies.

The efficiency of South Korean shipyards is evident in their operations. For instance, a recent visit to the Hyundai yard showcased a unique flatbed vehicle transporting large hull sections, with a team of workers ensuring safe passage amidst busy operations. The yard employs strict safety protocols, underscoring the importance of worker welfare.

The potential for collaboration between South Korean shipbuilders and the U.S. Navy is increasingly on the horizon. In 2022, Hanwha acquired Philly Shipyard in Pennsylvania, committing to invest $5 billion to enhance both commercial and military capabilities. Similarly, Hyundai is looking to expand its presence in the U.S. market.

However, U.S. law currently restricts the Navy from purchasing foreign-built ships, even from allied nations like South Korea. This limitation is rooted in national security concerns and the desire to protect domestic shipbuilding. Recent immigration issues surrounding a Korean battery plant in Georgia have further complicated U.S.-Korean relations, raising concerns about future cooperation.

A recent agreement between the U.S. and Finland, which involves constructing four Coast Guard icebreakers in Finnish shipyards, may serve as a model for potential naval shipbuilding collaborations. Nevertheless, different regulations apply to the Navy and Coast Guard, complicating any similar arrangements.

Mercogliano suggests that Congress could reconsider requirements for auxiliary and supply vessels, potentially allowing for more overseas shipbuilding initiatives. Hanwha’s Jeon Yu-su expressed a clear ambition when asked about the possibility of constructing U.S. warships at the Geoje shipyard, stating, “Yes!”

As the U.S. Navy confronts its shipbuilding crisis, the expertise and capabilities of South Korean shipyards could play a pivotal role in shaping the future of naval construction.

-

Science2 months ago

Science2 months agoOhio State Study Uncovers Brain Connectivity and Function Links

-

Politics2 months ago

Politics2 months agoHamas Chief Stresses Disarmament Tied to Occupation’s End

-

Science1 month ago

Science1 month agoUniversity of Hawaiʻi Joins $25.6M AI Project for Disaster Monitoring

-

Science4 weeks ago

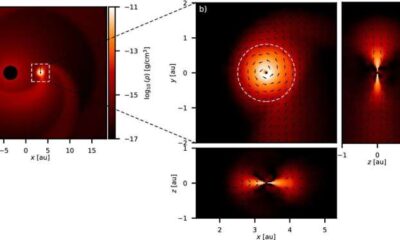

Science4 weeks agoALMA Discovers Companion Orbiting Giant Star π 1 Gruis

-

Entertainment2 months ago

Entertainment2 months agoMegan Thee Stallion Exposes Alleged Online Attack by Bots

-

Science2 months ago

Science2 months agoResearchers Challenge 200-Year-Old Physics Principle with Atomic Engines

-

Entertainment2 months ago

Entertainment2 months agoPaloma Elsesser Shines at LA Event with Iconic Slicked-Back Bun

-

World1 month ago

World1 month agoFDA Unveils Plan to Cut Drug Prices and Boost Biosimilars

-

Business2 months ago

Business2 months agoMotley Fool Wealth Management Reduces Medtronic Holdings by 14.7%

-

Science2 months ago

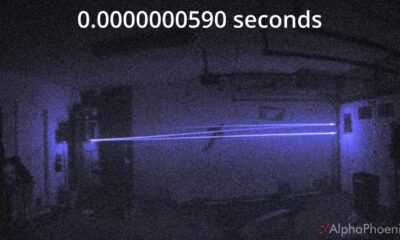

Science2 months agoInnovator Captures Light at 2 Billion Frames Per Second

-

Top Stories2 months ago

Top Stories2 months agoFederal Agents Detain Driver in Addison; Protests Erupt Immediately

-

Entertainment1 month ago

Entertainment1 month agoBeloved Artist and Community Leader Gloria Rosencrants Passes Away