Health

Muzzleloader Maintenance: Key Steps for Hunters After Season Ends

The end of big game hunting season does not mark the end of responsibilities for muzzleloader owners. Proper maintenance is essential to ensure these firearms remain in excellent condition. Many hunters may overlook this critical step, but neglecting to clean and store muzzleloaders can lead to misfires and operational failures when the next hunting season arrives.

Importance of Cleaning Muzzleloaders

Muzzleloaders have evolved significantly since their inception. In the early 1980s, the introduction of in-line breech designs transformed the ignition systems, making them more reliable and user-friendly. Today, statistics indicate that over 95% of deer taken in the United States with muzzleloaders are hunted using in-line models. This design has gained popularity among hunters who appreciate its ease of use and efficiency.

The in-line muzzleloader’s breech plug is a crucial component for maintaining reliability. Unlike traditional muzzleloaders, in-line models feature a screw-in design that simplifies cleaning. However, without regular maintenance, residue can accumulate, leading to potential misfires. Proper cleaning after every use is essential to prevent issues related to seized plugs and ignition failures.

Steps for Effective Maintenance

Cleaning the breech plug is straightforward yet vital. To begin, remove the plug and thoroughly clean the threads, primer pocket, and fire channel. A solution specifically designed for muzzleloaders, such as Birchwood Casey No. 77 or Thor’s MZ Breech Plug Solution, is recommended for soaking the plug. A small brush can be used for scrubbing, while a nipple pick is effective for clearing the fire hole. Compressed air is useful for removing any remaining moisture.

After cleaning, reinsert the breech plug using an anti-seizing lubricant that withstands high temperatures, such as Thompson/Center’s Gorilla Grease or Thor’s MZ Ceramic Anti-Seize. Following a consistent maintenance routine will help ensure that ignition issues are minimized.

In addition to the breech plug, the firing pin in break-open models also requires attention. Residue or rust can cause the firing pin to stick, affecting performance. A simple solution involves applying a drop of oil, working the hammer back and forth, and dry firing once or twice while wiping away excess oil.

Storage practices are equally important. It is advisable to store muzzleloaders muzzle-end down to prevent cleaning solvents or oils from seeping into the breech plug. Ideally, storing firearms in a safe equipped with a dehumidifier is the best practice. If that is not feasible, a hard gun case with reusable desiccant packs can effectively manage moisture levels.

As the hunting season concludes, proper care for your muzzleloader ensures it remains ready for future use. By maintaining and storing your equipment correctly, you can enjoy a successful hunting experience when the next season arrives.

-

Science2 months ago

Science2 months agoOhio State Study Uncovers Brain Connectivity and Function Links

-

Science1 month ago

Science1 month agoUniversity of Hawaiʻi Joins $25.6M AI Project for Disaster Monitoring

-

Politics2 months ago

Politics2 months agoHamas Chief Stresses Disarmament Tied to Occupation’s End

-

Science4 weeks ago

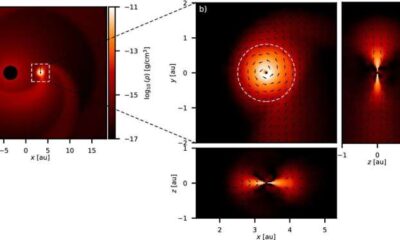

Science4 weeks agoALMA Discovers Companion Orbiting Giant Star π 1 Gruis

-

Entertainment2 months ago

Entertainment2 months agoMegan Thee Stallion Exposes Alleged Online Attack by Bots

-

Science2 months ago

Science2 months agoResearchers Challenge 200-Year-Old Physics Principle with Atomic Engines

-

Entertainment2 months ago

Entertainment2 months agoPaloma Elsesser Shines at LA Event with Iconic Slicked-Back Bun

-

World2 months ago

World2 months agoFDA Unveils Plan to Cut Drug Prices and Boost Biosimilars

-

Science2 months ago

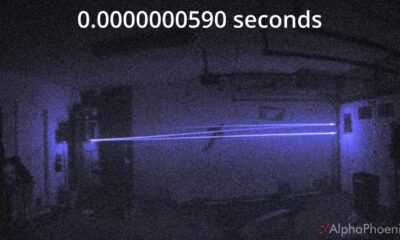

Science2 months agoInnovator Captures Light at 2 Billion Frames Per Second

-

Top Stories2 months ago

Top Stories2 months agoFederal Agents Detain Driver in Addison; Protests Erupt Immediately

-

Business2 months ago

Business2 months agoMotley Fool Wealth Management Reduces Medtronic Holdings by 14.7%

-

Entertainment2 months ago

Entertainment2 months agoBeloved Artist and Community Leader Gloria Rosencrants Passes Away