Science

Algorithms Illuminate Propane Conversion to Propylene Breakthrough

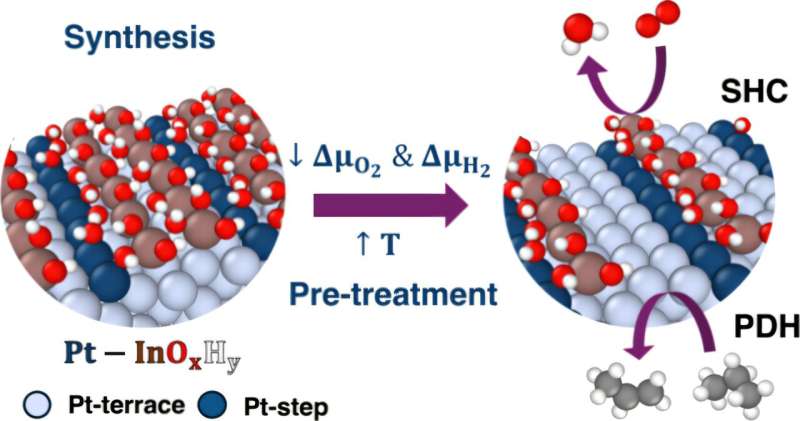

Innovative algorithms developed at the University of Rochester have unveiled the atomic mechanisms involved in converting propane into propylene, a crucial step for manufacturing everyday products. This research, published on November 13, 2025, in the Journal of the American Chemical Society, enhances the understanding of a process essential for creating items ranging from plastic bottles to outdoor furniture.

In prior work, a study published in 2021 in Science demonstrated that chemists could utilize tandem nanoscale catalysts to streamline the conversion process. However, the atomic details of this complex reaction remained elusive, hindering broader applications in industrial chemistry. The recent study addresses this gap by focusing on the intricate interactions at the atomic level during the catalytic process.

Decoding Complex Reactions

The research team, led by Assistant Professor Siddharth Deshpande, employed advanced algorithms to analyze the myriad of atomic interactions that occur when nanoscale catalysts facilitate the transformation of propane into propylene. “There are so many different possibilities of what’s happening at the catalytic active sites, so we need an algorithmic approach to very easily yet logically screen through the large amount of possibilities that exist and focus on the most important ones,” Deshpande explained.

The team, including Ph.D. student Snehitha Srirangam, discovered unexpected behaviors in their findings. They noted that the oxide formed during the reaction showed a strong preference for surrounding defective metal sites, which proved vital for maintaining the stability of the catalyst. Despite the oxide’s ability to exist in various chemical compositions, it consistently remained associated with these defective sites, emphasizing the significance of this interaction.

Broader Implications for Industrial Chemistry

Deshpande believes that the insights gained from this research can significantly impact how companies approach the production of propylene and other industrial materials. By leveraging the team’s algorithmic methods, researchers could enhance the understanding of other critical chemical processes, such as methanol synthesis, which is used in the production of products like paints and fuel cells.

“Our approach is very general and can open the doors to understanding many of these processes that have remained an enigma for decades,” Deshpande remarked. He emphasized that while the production of these chemicals is prevalent, the underlying mechanisms are not fully understood. This work offers a pathway to move beyond traditional trial-and-error methods that have characterized industrial chemistry for years.

The team’s findings represent a significant step forward in the field, potentially leading to more efficient and cost-effective production methods for essential chemicals. As industries seek to improve their processes, this research could pave the way for innovations that enhance productivity and sustainability in chemical manufacturing.

-

Politics3 weeks ago

Politics3 weeks agoHamas Chief Stresses Disarmament Tied to Occupation’s End

-

Science2 weeks ago

Science2 weeks agoOhio State Study Uncovers Brain Connectivity and Function Links

-

Entertainment2 weeks ago

Entertainment2 weeks agoMegan Thee Stallion Exposes Alleged Online Attack by Bots

-

Science4 weeks ago

Science4 weeks agoResearchers Challenge 200-Year-Old Physics Principle with Atomic Engines

-

Entertainment2 weeks ago

Entertainment2 weeks agoPaloma Elsesser Shines at LA Event with Iconic Slicked-Back Bun

-

World2 weeks ago

World2 weeks agoFDA Unveils Plan to Cut Drug Prices and Boost Biosimilars

-

Top Stories3 weeks ago

Top Stories3 weeks agoFederal Agents Detain Driver in Addison; Protests Erupt Immediately

-

Business2 weeks ago

Business2 weeks agoMotley Fool Wealth Management Reduces Medtronic Holdings by 14.7%

-

Business2 weeks ago

Business2 weeks agoHome Depot Slashes Prices on Halloween Favorites Up to 75%

-

Entertainment2 weeks ago

Entertainment2 weeks agoBeloved Artist and Community Leader Gloria Rosencrants Passes Away

-

Top Stories3 weeks ago

Top Stories3 weeks agoOrioles Hire Craig Albernaz as New Manager Amid Rebuild

-

Entertainment3 weeks ago

Entertainment3 weeks agoSyracuse Stage Delivers Lively Adaptation of ‘The 39 Steps’